February 3, 2025

The Body of Orpheus: Part I

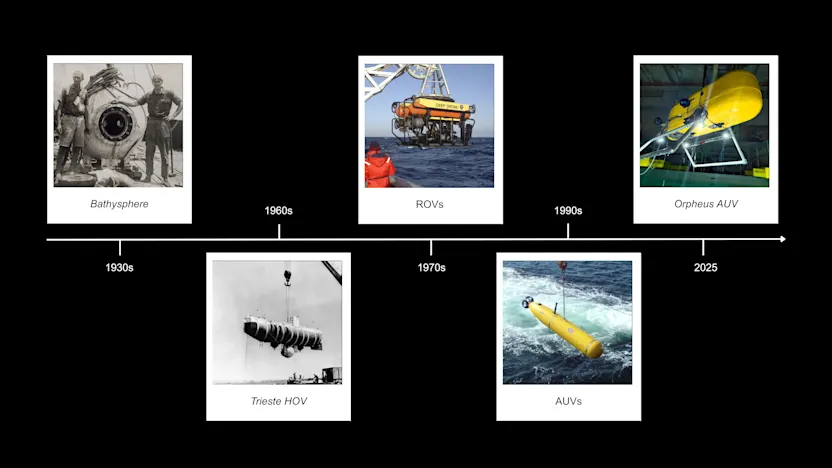

The team has designed our first product, the Orpheus benthic exploration AUV, with three core pillars in mind: flexibility, agility, and scalability. We’ll dive more into what these mean for us and for customers in the emerging blue economy in a future post, but for now we’re highlighting how the Orpheus AUV embodies these elements in every bolt, providing a reliable platform that streamlines access to deep seafloor environments. In honor of one of the ocean’s deepest diving mammals, we relate the parts of Orpheus to the anatomy of the magnificent sperm whale.

Like a heavy duty jigsaw puzzle.

We started the third Orpheus AUV prototype build in November 2024 and quickly became familiar with the local metalworking community in New Bedford, which is quite robust due to the thriving boating, fishing, and offshore wind industries. After getting pieces precision-cut from aluminum, we had them welded to construct the structural frame, or “skeleton,” of the vehicle. Aluminum is light and corrosion resistant, yet strong enough to stand up to extreme ocean forces, even after we cut out holes to minimize weight. Keeping the base weight as low as possible makes for facile transportation and launch-and-retrieval of the vehicle, and every ounce of extra weight is actually magnified due to the need for additional buoyancy to counteract it.

One eye-catching element of the Orpheus AUV frame is the pair of landing skids, which allows the vehicle to land on and physically interact with the seafloor for measurements or sample return. Additionally, the ability to land and enter a low-power stationary mode enables long-duration tasks previously requiring an entirely different type of asset. Although now truly vestigial in our cetacean reference, there is evidence that an evolutionary ancestor had stubby legs for crawling around on the beach.

Both heavier and lighter than you'd expect.

Next comes installation of our flotation system. Syntactic foam is an engineered material that contains millions of tiny hollow glass spheres suspended in a ceramic matrix. These spheres make the material lighter than water, providing buoyancy, while the matrix prevents it from being crushed under high pressures - even down to the deepest parts of the ocean. This combination of features makes syntactic foam an ideal material for deep sea vehicle flotation and we make full use of it as the molded body or “blubber” of the vehicle (alternatively “spermiceti” for the whale anatomy enthusiasts). The foam/vehicle ratio is precisely calibrated so that the whole system is as close to neutrally buoyant as possible, minimizing energy use at depth.

A body isn’t much use without its head. The “head” of our Orpheus AUV is split across two different compartments: the junction box and the sphere. The sphere (or “skull”) is made of extremely strong glass with the interior kept at atmospheric pressure, which enables many of our electronic systems (the “brains”) to function as normal. It’s also easily swappable for ease of maintenance, and serves a dual purpose as additional flotation, further cutting vehicle weight. The junction box (or “nervous system”) routes signals from the sphere to various components and payloads throughout the body.

Very much not bio-inspired: free rotation is found nowhere in the animal kingdom.

The Orpheus AUV makes use of two vertical and two horizontal thrusters, which allows for precise navigation near complex seafloor terrain, as well as hovering above and landing on the seafloor. These act as the “fins” and “tail” of the vehicle, enabling efficient movement through the water with four degrees of freedom.

Stackability is not a core design principle, but it's nice when it happens.

Our vehicle “skins” are custom molded by a specialty plastics group. Like real skin, they serve three important functions: 1) streamlining the profile of the vehicle to reduce drag while it’s in motion, ultimately conserving energy and increasing survey speed, 2) providing some basic protection in the case of collision with environmental obstacles, and 3) serving as a colorful visual signal to aid recovery (distinct from the camouflage of many ocean predators!).

Zoom in for our first branded product placement crossover event.

Up next, Part II of our build documentation will explore the sensor and payload systems that serve as the eyes and ears of the Orpheus AUV.

Join our newsletter for updates